|

|

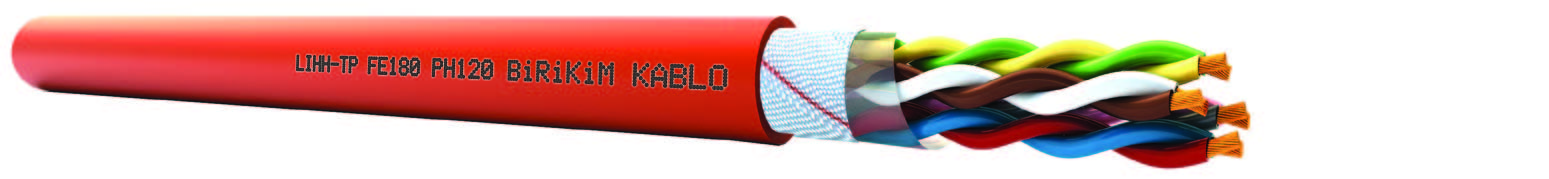

LIHH-TP FE180 PH120

| Application | ||||

|

These cables are used in industrial electronics, control engineering applications, electronic devices and automation systems, fire alarm and supression systems especially in public buildings such as hotels, schools, hospitals, shopping centers etc. They have low smoke density and they don’t emit poisonous and corrosive gases during a fire therefore they don’t harm human health. They can function under flame for 180 minutes according to tests done as per IEC 60331-21 and maintain 120 minutes circuit integrity according to tests done as per EN50200 which simulate the fire and hazardous conditions. |

||||

| Construction | ||||

| Conductor | IEC 60228, EN 60228, VDE 0295 CLASS-5 Stranded electrolytic annealed copper wire | |||

| Insulation | Cross-linked elastomer silicone insulation | BS EN 50363-1, HD 22.1 S4(EI2) | |||

| Colour Code | DIN 47100 | |||

| Lay up | Two cores twisted in pair and pairs stranded together | |||

| Separator | Polyester tape | |||

| Flame Barrier | Fiberglass tape | |||

| Outher sheath | HFFR | EN 50290-2-27, VDE0207(HM2) | |||

| Outher Sheath Colour | RAL 2004 Orange | |||

| Specifications | ||||

| Conductor Resistance | ||||

| Cross section (mm2) | Ω/km (max.) | |||

| 0,75 | 26 | |||

| 1,0 | 19,5 | |||

| 1,5 | 13,3 | |||

| 2,5 | 7,98 | |||

| Insulation Resistance | >200MΩ.km | |||

| Operating Voltage | 300/500 V | |||

| Test Voltage | 1000 V | |||

| Temperature Range | -30°C – +90°C (fixed) | |||

| Min. Bending Radius | 7,5 x cable diameter | |||

| Flame tests | IEC 60332-1-2, EN 60332-1-2, VDE 0482-332-2-1 | |||

| Smoke Density | IEC 61034-2, EN 61034-2 | |||

| Corressive Gas Tests | IEC 60754-1, EN 50267-2 | |||

| Circuit Integrity Tests FE180 | IEC 60331-21 | |||

| Circuit Integrity Tests PH120 | EN 50200 | |||

| Product Code | Number of Cores ×Cross Section (mm²) | Cable Diameter (mm ±5%) | Copper Weight (kg/km) | Cable Weight (kg/km) |

| 3401120802 | 2x2x0,75 | 8,4 | 26,5 | 69 |

| 3401120803 | 3x2x0,75 | 9,5 | 41 | 98 |

| 3401120804 | 4x2x0,75 | 10,9 | 54 | 135 |

| 3401120805 | 5x2x0,75 | 11,8 | 68 | 162 |

| 3401120806 | 6x2x0,75 | 12,3 | 80 | 182 |

| 3401120808 | 8x2x0,75 | 13,4 | 104 | 220 |

| 3401120810 | 10x2x0,75 | 15,8 | 131 | 285 |

| Product Code | Number of Cores ×Cross Section (mm²) | Cable Diameter (mm ±5%) | Copper Weight (kg/km) | Cable Weight (kg/km) |

| 3401121002 | 2x2x1,00 | 8,8 | 36 | 88 |

| 3401121003 | 3x2x1,00 | 10,2 | 53 | 124 |

| 3401121004 | 4x2x1,00 | 11,7 | 71 | 160 |

| 3401121005 | 5x2x1,00 | 12,4 | 90 | 192 |

| 3401121006 | 6x2x1,00 | 12,9 | 107 | 240 |

| 3401121008 | 8x2x1,00 | 14 | 143 | 305 |

| 3401121010 | 10x2x1,00 | 15,7 | 181 | 370 |

| Product Code | Number of Cores ×Cross Section (mm²) | Cable Diameter (mm ±5%) | Copper Weight (kg/km) | Cable Weight (kg/km) |

| 3401121502 | 2x2x1,50 | 11 | 52 | 128 |

| 3401121503 | 3x2x1,50 | 11,9 | 77 | 174 |

| 3401121504 | 4x2x1,50 | 13,8 | 103 | 224 |

| 3401121505 | 5x2x1,50 | 15,4 | 130 | 270 |

| 3401121506 | 6x2x1,50 | 16,2 | 154 | 330 |

| 3401121508 | 8x2x1,50 | 17,1 | 206 | 422 |

| 3401121510 | 10x2x1,50 | 19,4 | 260 | 540 |

| Product Code | Number of Cores ×Cross Section (mm²) | Cable Diameter (mm ±5%) | Copper Weight (kg/km) | Cable Weight (kg/km) |

| 3401122502 | 2x2x2,50 | 12,5 | 85 | 185 |

| 3401122503 | 3x2x2,50 | 14 | 128 | 252 |

| 3401122504 | 4x2x2,50 | 16,2 | 171 | 330 |

| 3401122505 | 5x2x2,50 | 17,5 | 214 | 410 |

| 3401122506 | 6x2x2,50 | 18,8 | 257 | 505 |

| 3401122508 | 8x2x2,50 | 20 | 343 | 655 |

| 3401122510 | 10x2x2,50 | 21,8 | 430 | 805 |

Address: Akcaburgaz Mah. 3109. Sok No:3/3 Esenyurt/Istanbul/TURKEY

Phone: +90 212 672 92 24 (pbx) - Fax: +90 212 672 92 26

E-mail: birikim@birikimkablo.com - Export: export@birikimkablo.com

Phone: +90 212 672 92 24 (pbx) - Fax: +90 212 672 92 26

E-mail: birikim@birikimkablo.com - Export: export@birikimkablo.com